Rescue operation underway to trace workers trapped inside the partially collapsed Telangana’s Srisailam Left Bank Canal tunnel, in Nagarkurnool district on Tuesday (March 4, 2025).

HYDERABAD

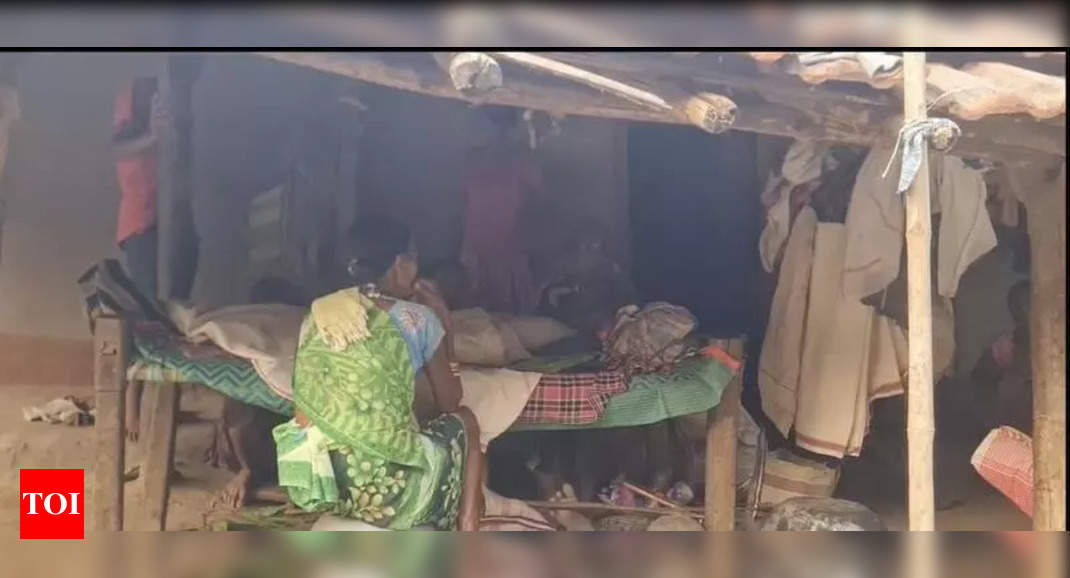

There seems to be no end in sight to the agonising wait of family members of eight persons trapped under the debris about 14 km inside the Srisailam Left Bank Canal (SLBC) tunnel from February 22 morning as the debris and mud removal work to trace those trapped is stretching on, despite the conveyor belt becoming functional on Tuesday evening.

The task of cutting the tunnel boring machine (TBM) which was damaged badly in the roof collapse, shifting of that debris and removal of mud in the last 20 metres stretch of the tunnel excavated so far remains highly challenging, though the conveyor belt has been restored after 10 days of hard work, a senior official involved in the rescue work said.

“The conveyor belt is not a panacea to all issues inside the tunnel, it may only step up the mud shifting work after testing. Originally, the conveyor belt was linked and synchronised with the functioning of the TBM and it would shift the excavated material, soil mixed with small stones up to six-inch diameter, channelised and loaded automatically onto the belt from the TBM,” the official explained.

The conveyor belt to carry out excavated material from the tunnel boring machine has been restored t the Srisailam Left Bank Canal tunnel, but its utility cannot be determined without testing, say officials.

| Photo Credit:

NAGARA GOPAL

Now that it is restored to function independently, it is not known how it would serve the purpose until five-six hours of testing is done. Further, loading the mud on to the conveyor belt, which is fixed to a side/wall of the tunnel at about 3 metres elevation, manually too would be both laborious and complex as it has been restored only up to 13.5 km from the tunnel mouth, leaving another 400-odd metres to be dealt with separately.

However, the shifting of metal parts of the TBM cut into pieces has to be done through locomotive trolleys itself as the conveyor belt would not carry metal parts since they would damage the belt and get stuck.

On the exercise of dewatering, a senior engineer said that water seepage of about 3,500 litres per minute is getting accumulated at different spots and they are using a five-stage pumping facility with a total capacity of 2,200 HP motors to pump the water out of the tunnel.

The officials, however, are unable to give any timeline to find the trapped persons due to the difficulties involved in the mud and debris removal work despite the personnel from Singareni Collieries Company Ltd and South Central Railway workinng hard to remove the debris.

Published – March 04, 2025 08:38 pm IST